Injection molds and PCB depanelization tools

We have a modern and automated injection molding plant that allows us to obtain thousands of elements a day.

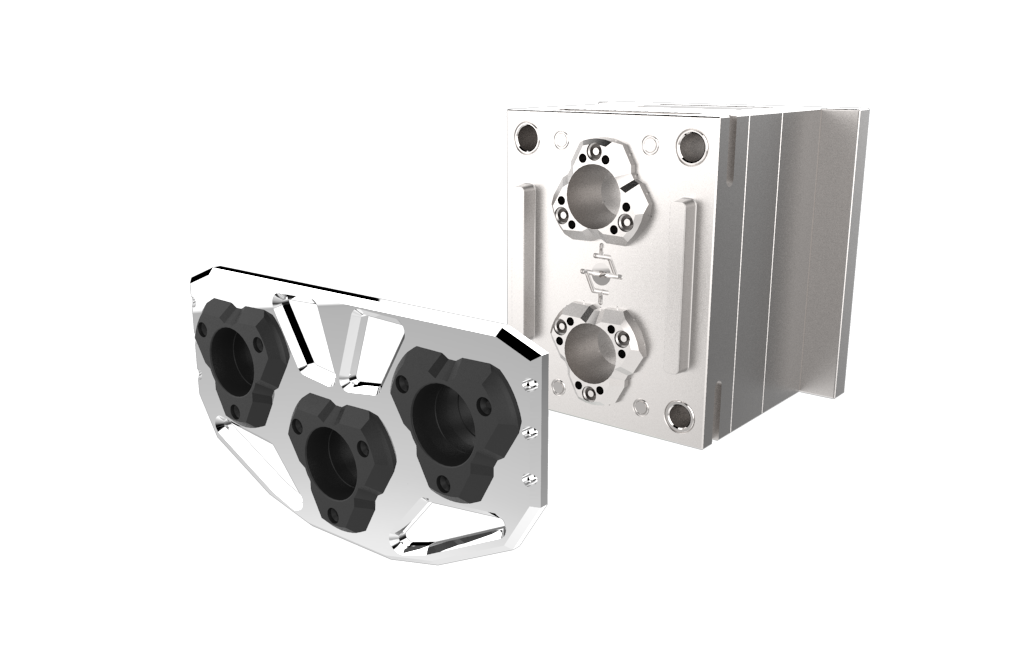

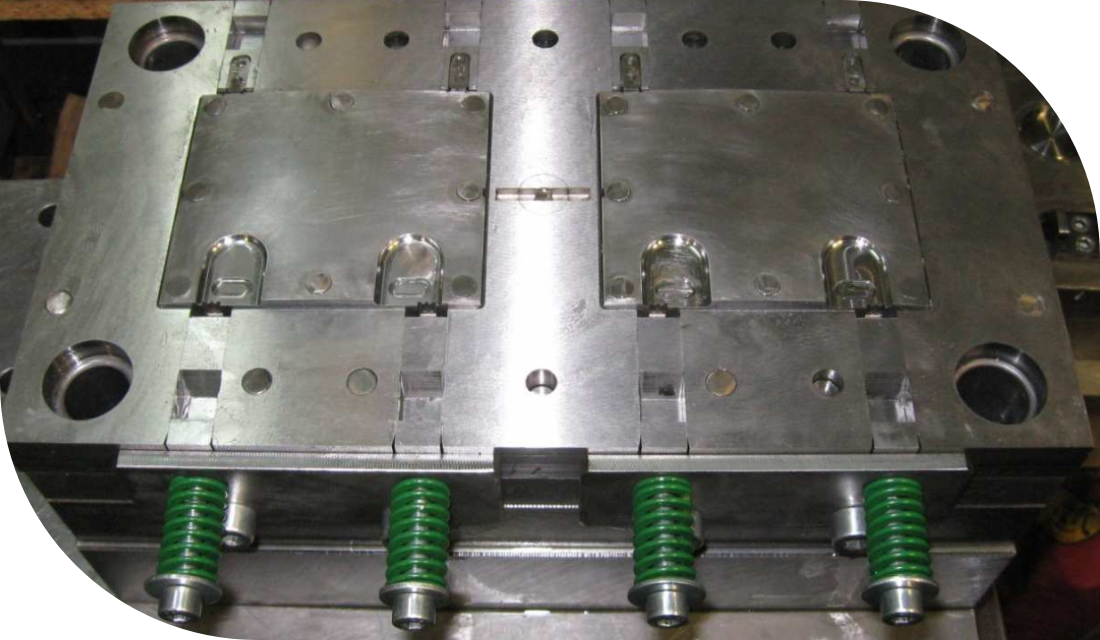

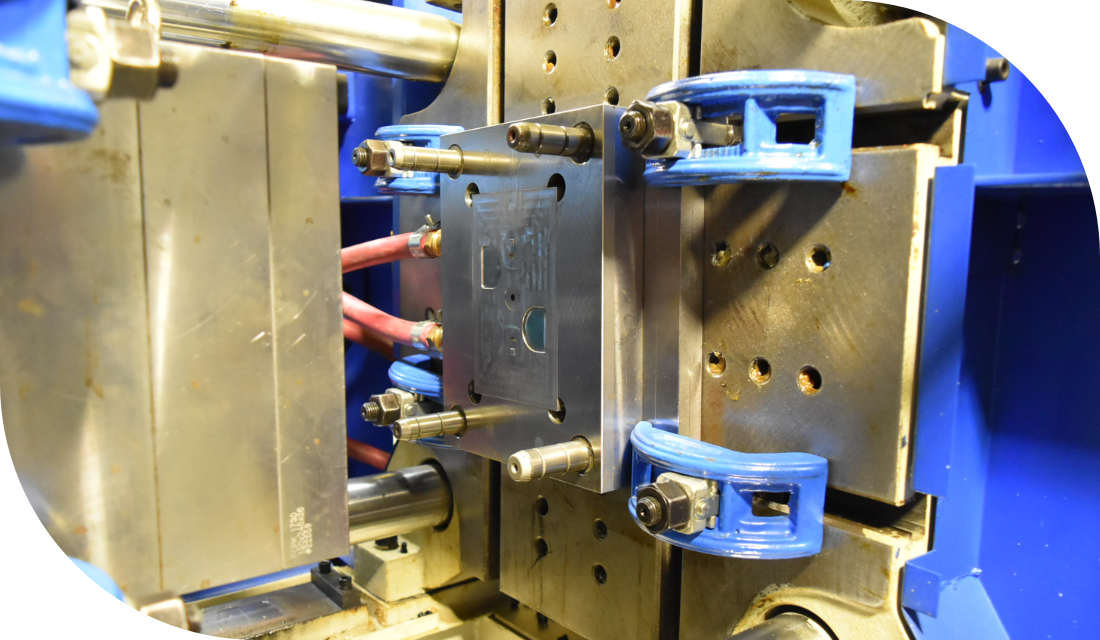

Injection molds

Plastic processing

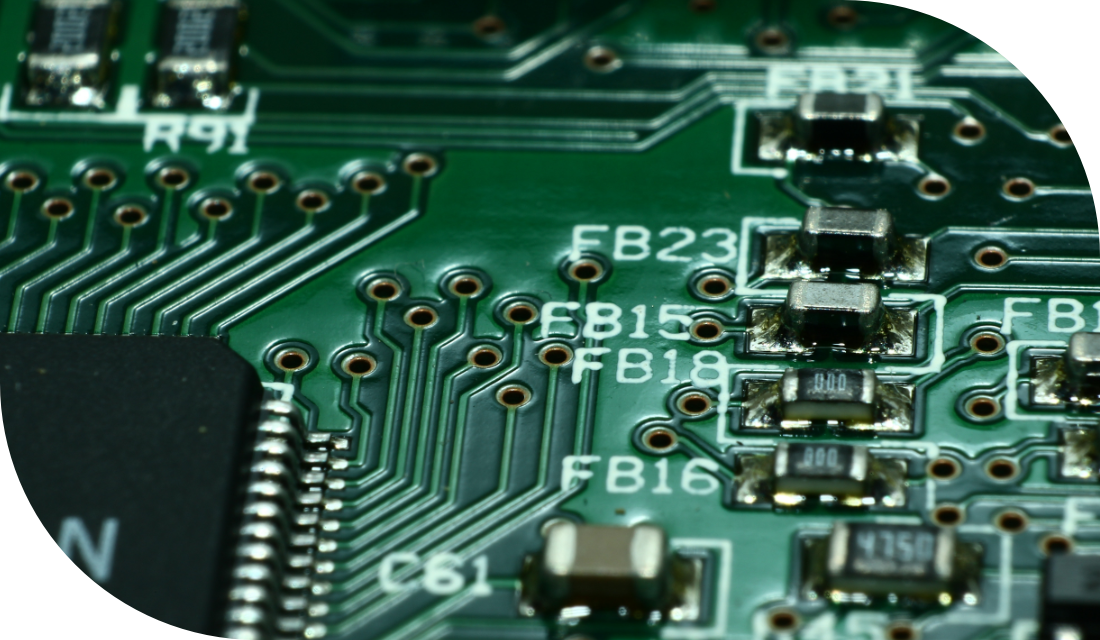

PCB depaneling tools

Injection molds

Injection molding - plastic molding technique consisting in injecting plasticized material into the mold, in which it solidifies (solidifies) in the so-called a molding (fitting). Injection molding (shortly: injection) is a cyclical process of processing plastics in the form of granules.

There is also a variation of injection molding in which not the finished granulate is used, but a prepolymer and an agent causing it to polymerize during the molding process. This type of injection is called reactive injection molding.

The injection molding process is carried out in special devices called injection molding machines. Injection is used to mold thermoplastics or thermosets.

PCB depanelization

PCB depanelization is a process step in the production of large-scale assembly of electronics. To increase the throughput of printed circuit board (PCB) and surface mount (SMT) production lines, printed circuit boards are often designed to consist of many smaller individual printed circuit boards that will be used in the final product. This PCB cluster is called a panel or multi-block. The large panel is broken or "depanellated" as a process step - depending on the product, this can be right after the SMT process, after the in-circuit test (ICT), after soldering through-hole components, and even just before the final assembly of the PCBA in the enclosure.

Send your inquiry today!

office@dameks-cnc.eu

dameks@dameks-produkcja.com.pl

or call us:

+48 607 039 008

+48 601 674 458

We operate continuously

Domestic and European shipping

Take care of your business